Welcoming Customers to METALTECH & AUTOMEX 2024. It is a great honour to have them as part of the event with us at booth #8182

Metaltech, hosted annually at the MITEC Malaysia International Trade & Exhibition Centre in Kuala Lumpur, is a premier trade fair for metal processing and machine tools. It attracts professionals from diverse industries such as aerospace, automotive, marine/offshore, and more from countries like Thailand, Vietnam, Malaysia, Singapore, and Korea.

The event showcases a wide array of metal processing machines, and production lines, providing professionals with the opportunity to compare and select products directly on-site. Metaltech serves as a key platform for knowledge exchange, technological advancements, and strategic planning within the industry, solidifying its position as the leading trade fair in the region.

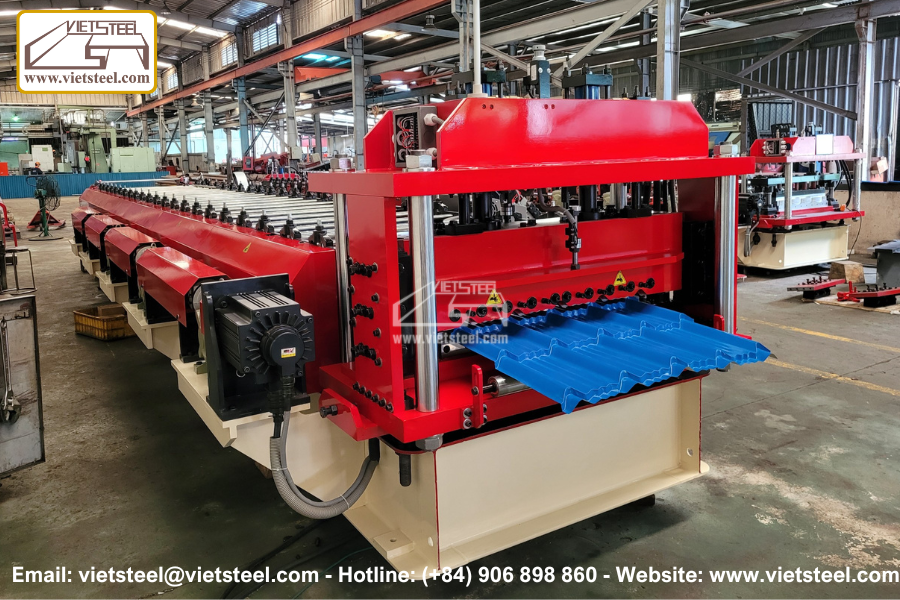

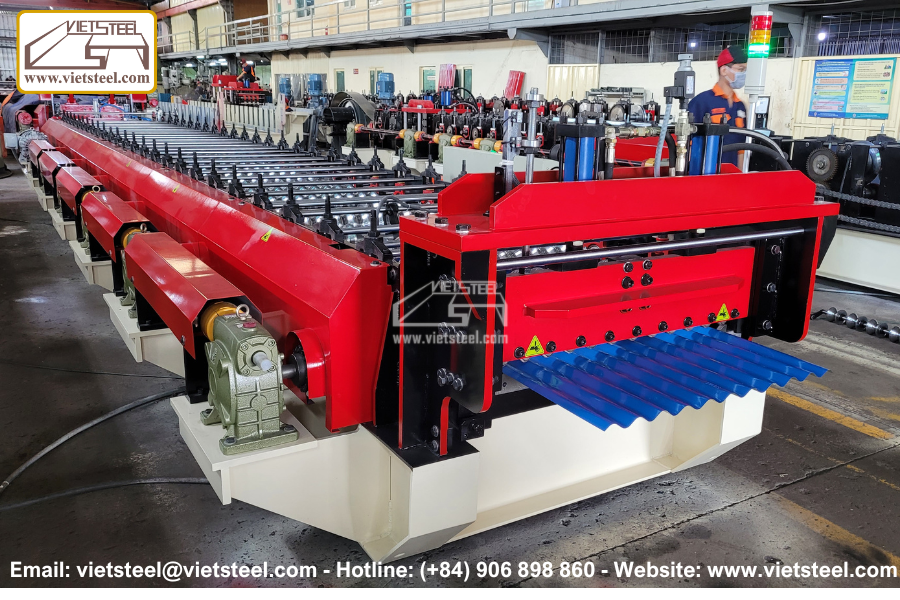

At Vietsteel Machinery, we are Vietnam’s foremost experts in designing, manufacturing, and installing a wide range of roll forming, bending, cutting, and punching machines. Now, we’ll be introduce and showcase our best-selling products our specialization lies in Roofing Roll Forming Machines, Steptile Roll Forming Machines, Decking Roll Forming Machines, Cable Tray Roll Forming Machines, Smartframe Solutions and Applications – Lightframe Steel, and Purlin Roll Forming Machines,…

Specially, Hot deal in May, your discount 5% when you message your Full name & email/phone number, registering to the participate requesting a quotation, you will be Discount On Roll Forming Machines For This Time.

Register today at https://forms.gle/czPJyp1wmT7DCCnK6

The popular functions of metal roll forming machines Vietsteel

Let go with Vietsteel Machinery discover the market leaders in roll forming machines with our handpicked selection of popular, each recognized for superior functionality and advanced features.

– Power:

+ Transmission: 7.5 – 22 kw

+ Motor – Pump: 5.5 – 7.5 kw

– Weight of machine: 9 – 19 tons

– Dimension: L=9-13m; W=1.5-2.0m; H=1.6m

– Forming speed: 30 meters/minute

+ 3 meters x 10 pcs/min

– Roller stations: 20-32

Power:

+ Transmission: 11 – 15 kw;

+ Motor-Pump: 15kw

Weight of machine: 12 – 18 tons

Dimension: L= 6 – 12 m; W= 2.3-2.6m; H=1.6 m

Forming Speed: 8 meters/minute

Roller stations: 12 – 26

Forming speed: Transmission: 2x15kw – 1/30 1×7.5kw – 1/30

Motor – pump: 11kw – 45cc

Size changed: 3×1.5kw – 1/25

Punch table: 2×1.5kw

Weight of machine: 28 tons

Dimension: L=16m; W=2.5m; H=2m

Forming speed: 16 – 20 meters/ minute

Roller stations: 12 – 26

– Power: + Transission: 11kW + 11 kw

+ Motor – Pump: 11 kw

– Weight of machine: 20-24 tons

– Dimension: L=13-15m; W=2.3-2.6m; H=1.7m

– Forming speed: Steptile deck: 5mpm

+ Rooofing deck: 30 mpm

Roller stations: 12 – 32

Power: Motor 7.5 kW (3 phase, 50 Hz, 380 V)

Weight of machine : 4 tons

Dimension : 4.5m x 0.6m x 1.4m

Roller Station: 12-14

Forming Speed: 20 mpm

Power:

+ Transmission: 11 kW

+ Motor – Pump: 5.5 kW

Weight of machine: 6 – 7 tons

Dimension: L=6.0-7.5m; W=1m; H=1.6m

Forming speed: 25 – 30 meters/ minute

– Power:

Motor – Pump: 11 – 22 kw

– Weight of machine: 14 – 18 tons

– Dimension: L=12-14m; W=1.5-2.0m; H=1.6m

– Forming speed: 20 meters/minute

+ 3 meters x 6.5 pcs/min

– Roller stations: 20-32

Power:

+ Transmission: 11 – 15 kw;

+ Motor-Pump: 11kw

Weight of machine: 30 tons

Dimension: L= 14 m; W= 2.0m; H=1.8 m

Forming Speed: 1-6 meters/minute

Roller stations: 24

Power: Transmission: 22 kW-30 kW,

Motor-pump: 11 -15kw

Weight: 20 -25 tons (according to profile)

Dimensions: L = 12-22m ; W = 2.1m ; H = 1.9m

Number of pairs: 32 – 42

Forming speed: 16 -20mpm

– Power: + Transission: 11kW

+ Motor – Pump: 7.5 kw

– Weight of machine: 5 tons

– Dimension: L=5..2m; W=1.6m; H=1.9m

– Forming speed: 8-10mpm

Roller stations: 7

– Power: + Transission: 7.5-15kW

Feeding: 1.5kW

– Weight of machine: 7.5-13.5 tons

– Dimension: L=4.5-10.5m; W=1.7m; H=1.9m

– Folding speed: 12 seconds/stroke

Folder angle minimum: 45 degree

Power:

+ Transmission: 15 – 22 kW

+ Motor – Pump: 7.5 kW

Weight of machine: 14 – 16 tons

Dimension: L=12-14m; W=1.9m; H=1.7m

Forming speed: 22 – 25 meters/ minute

Advanced features Roll Forming Machine

Advanced features

With Rotary-cut technology, the machine achieves speed up to 60 meters/min. This is a new technology, reaching the highest speed ever of Vietsteel. The quality of the roofing sheet is also rated as the best, the least defective product, a continuous operating frequency of 20-22 hours/day. Components, encoders, engines, control panels … are imported from Japan, Taiwan, and Switzerland.

Roll Forming Machine automatically laminates and cuts to any length with a preset quantity and alarm to pre-cut before the order finished

Easily count the total length of the finished roll through the control panel

The rollers are alloy steel fabricated by CNC precision machine and hard chromium plated

The cutting die is SKD11 steel fabricated by CNC machine, thermal treatment reaches 55-60HRC.

The hydraulic system is equipped with a cooling system to afford the machine operating continuously from 20 hours to 22 hours per day.

- Working Flow All Kinds of Roll Forming Machine

Uncoiler -> Guide -> Pre-cutting -> Roll Forming Machine -> Profile cutting -> Run-out Product

Manufacturing and Quality Commitment Vietsteel Machinery :

Vietsteel Machinery takes pride in manufacturing all of its machines professionally and reasonably in Vietnam.

The company is dedicated to offering flexible machines of the highest quality with customized designs.

Prioritizing quality and customization ensures that machines meet specific customer needs and enhance overall performance and efficiency.

Vietsteel aims to provide a personalized touch that aligns with each customer’s preferences.

Customer Satisfaction and Long-Term Relationships:

Vietsteel’s commitment to customer satisfaction is reflected in its approach of delivering unique benefits and experiences.

The company strives to establish long-term relationships with its customers, contributing to their success in the industries they operate in.

Currently, the market offers a variety of metal sheet rolling machines, and selecting the most suitable one for a company’s production model remains a concern for many investors.

6.1. Choosing a rolling machine based on the company’s practical needs

The first step is to calculate the actual production needs of the company. Each sheet production unit serves different customer segments, each requiring different types of sheets. Selecting the most suitable metal sheet rolling machine optimizes machinery investment costs, saves on labor, and reduces production expenses.

Key questions to consider:

- What type of roll forming machine fits the workshop area?

- What are the maximum and minimum dimensions of sheets producible?

- What material is being processed?

- What is the sheet thickness?

- Is the machine price within the company’s financial capacity?

Based on this data, suppliers can advise on the most suitable and cost-effective metal sheet rolling machine.

6.2. Choose a reputable supplier with a well-known brand

The brand of the rolling machine significantly influences customer investment decisions. Companies offering quality product lines, favorable pricing, and excellent after-sales service build a reputable brand. Choosing a product based on brand reputation and customer experiences ensures the quality of the rolling machine.

6.3. Consider after-sales service and warranty

After-sales service and warranty are crucial factors. Vietsteel Machinery Co., Ltd understands the importance of post-sale care. They provide installation, repair, and warranty services by a knowledgeable, experienced team. Prompt technical support ensures uninterrupted production.

Reasons to choose VIETSTEEL:

- 25 years of roll forming machine expertise

- Delivered 5000 machines to 500 customers in 41 countries

- Products with almost absolute precision

- 15-year stable machine operation with 1-year warranty

- 24/7 professional customer support

- Strong financial capacity guarantees on-time delivery

- 140+ experienced employees and 2 factories with quality control equipment

For the best quotation and products, contact Vietsteel now: Phone: +84 906 898 860 Email: vietsteel@vietsteel.com Website: www.vietsteel.com