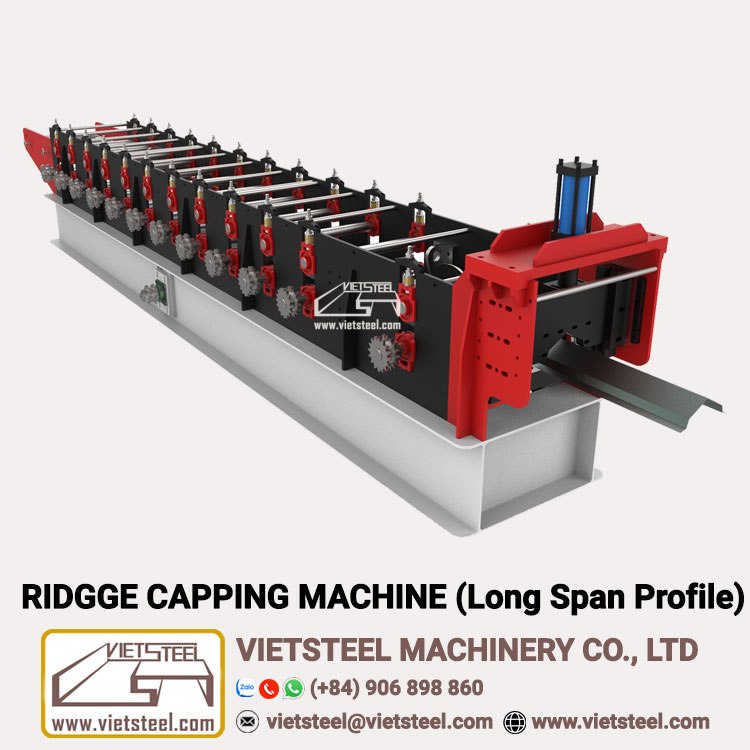

Description

Power: + Motor – Pump: 7.5kw

Weight of machine: 4-6 tons

Dimension: L=6-7m; W=0.8m; H=1.5m

Forming speed: 20 meters/ minute

Roller stations: 14-16

Automatically forming and cutting at any length with pre-set quantity.

Automatically alarm to pre-cut before the order finished.

Signal feedback from encoder showing existing length of product.

The control panel enables to count a total length of finished coil.

Rollers are alloy steel made by CNC precision machine and hard chromium plated get 45-48HRC.

Embossing rollers: S48 – 52C made by CNC precision machine, thermal treatment withhard chromium plated get 50-55HRC.

Cutting die is SKD11 steel made by CNC machine, thermal treatment get 55-60HRC.

Hydraulic system is equipped with a cooling system to afford the machine operating continuously from 20 to 22 hours per day.