Unlock the potential of floor decks, decking floors, and steel decking roll forming machines by aligning with Vietsteel. We’ll explore their definitions, structures, applications, advantages and disadvantages, and the right way to fabricate them. Let’s get started!

Nội dung chính

1. What is a floor deck?

A floor deck, also known as a metal floor deck, is a structural component used in building construction. It consists of a steel corrugated sheet with embossed patterns that create grooves with regular spacing. The primary purpose of a floor deck is to provide a stable base for pouring concrete, creating composite floors in multi-story buildings.

Wave Patterns: The deck slab is typically rolled into sheets with 50mm to 75mm high waves or corrugations. These waves add strength and rigidity to the sheet.

Thickness and Galvanization: Floor deck sheets are available in various thicknesses, commonly ranging from 0.75mm to 1.5mm. To prevent corrosion and rust, the sheets are often galvanized on both sides.

2. Application of Floor Deck

Application:

The floor deck plays a critical role in the construction process and offers several advantages in various applications:

The floor deck is connected to the steel structural beam system using welding nails, effectively replacing the traditional floor formwork. It combines with the reinforced concrete floor, significantly accelerating the construction progress compared to conventional reinforced concrete floors.

Once the metal floor decking is laid and securely fastened to the support structure, it forms the base for structural concrete to be poured over it. This concrete becomes an integral part of the floor’s structural system.

Floor deck is widely employed in commercial and industrial buildings, multi-story structures, warehouses, and parking garages due to its load-bearing capacity and stability.

Floor deck solution applications:

The Floor deck solution is versatile and applicable in various construction projects, including:

Construction of office floors within factory settings.

Floors in high-rise steel frame buildings, including office spaces.

Floors in restaurants, showrooms, and supermarkets.

Construction of steel frame townhouses.

3. Advantages and disadvantages of Steel Floordeck

Advantages:

Cost Savings: Steel decking floors offer cost savings as they reduce the amount of concrete required for structural purposes. Additionally, they are a faster construction alternative compared to cast-in-place concrete floors.

High Load-Bearing Capacity: Steel decking floors can handle large loads, making them suitable for projects with highly concentrated loads. The light steel grid system embedded within the concrete layer reinforces the floor, allowing it to withstand external impacts and heavy loads.

Durability and Aesthetics: These floors are highly durable and aesthetically pleasing. They eliminate the need for plastering or false ceilings, reducing both costs and construction time.

Lightweight: Steel decking is relatively lightweight when compared to other materials. This characteristic reduces the overall load pressure on the building.

Reduced Auxiliary Materials: Compared to traditional house types, steel decking requires fewer auxiliary materials, streamlining the construction process.

Space Optimization: Steel decking maximizes the use of factory space and allows for high synchronization in construction. It’s easy to scale up as needed.

Fire Resistance: Depending on the thickness of the floor and the type of concrete used, steel decking offers fire resistance. With simple reinforcement, it can be fire-resistant for up to 120 minutes, and additional reinforcement bars can further extend this fire resistance.

Floor deck is primarily used to support the weight of concrete, creating a sturdy and level surface for floors or roof decks. It eliminates the need for extensive formwork and reduces construction time.

Disadvantages:

Limited Shaping: Steel deck sheets are manufactured in a factory according to their standards, making it challenging to shape the floor slab for irregular or complex designs. They are best suited for square or rectangular floors.

Complex Structures: For floor slabs with triangular, circular, irregular polygonal shapes, or those with complex beam systems, steel decking can be difficult to construct and may not be the most effective solution. It is most suitable for straightforward, common square or rectangular floor designs.

Higher Initial Cost: Steel decking may have a higher initial cost compared to wood frame construction. However, steel structures are more durable and have a longer lifespan. Therefore, steel decking can be a more cost-efficient option for long-lasting buildings when considering the extended lifespan and reduced maintenance costs.

4. Floordeck Roll Forming Machine FD-EH Model

Floordeck Roll Forming Machine” is a piece of industrial equipment designed for roll forming or shaping metal sheets into floor decking or floor deck panels. This machine is commonly used in construction and building projects to create structural components for flooring systems.

Specifications of floordeck roll forming machine

Power – Transmission: 22 – 30kw

– Motor-Pump: 11 – 15kw

Weight of machine 20 – 25 tons

Dimension L = 12-22m ; W = 2.1m ; H = 1.9m

Forming Speed 16 – 20mpm

Roller stations 32 – 42

Transmission system Electric motor andGear box

Cutting system Hydraulic cylinder

Control system PLC, HMI automatic programmable

Material thickness 0.7 –1.6 mm

Material width 1200– 1250mm

Material Yield Strength G350 – G550 Mpa

Features Floordeck Roll Forming Machine

Automatically forming and cutting at any length with pre-set quantity.

Automatically alarm to pre-cut before the order finished.

Signal feedback from encoder showing existing length of product.

The control panel enables to count a total length of finished coil.

Rollers are alloy steel made by CNC precision machine and hard chromium plated get 45-48HRC.

Embossing rollers: S48 – 52C made by CNC precision machine, thermal treatment withhard chromium plated get 50-55HRC.

– Cutting die is SKD11 steel made by CNC machine, thermal treatment get 55-60HRC.

Hydraulic system is equipped with a cooling system to afford the machine operating continuously from 20 to 22 hours per day.

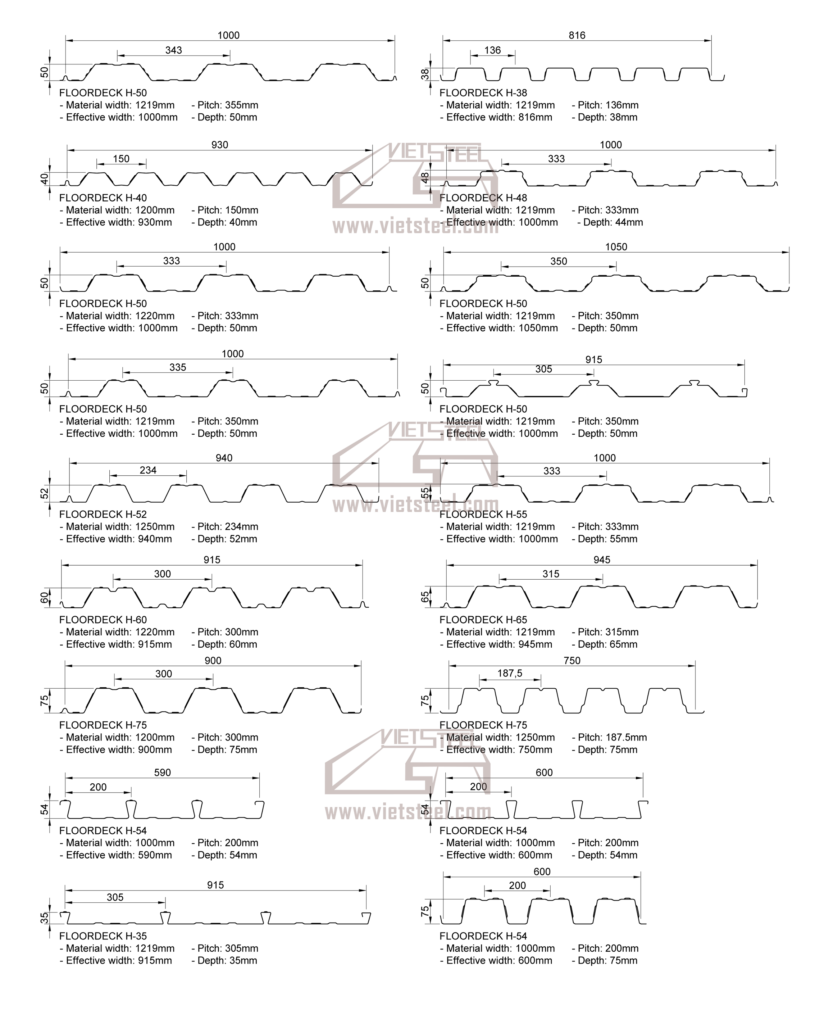

Floor Deck Profile

More information of Floordeck Roll Forming Machine: click here

5. Request a quotation for a floor deck roll forming machine

Vietsteel takes immense pride in its professional and cost-effective machine manufacturing in Vietnam. The company’s primary objective is to produce high-quality machines with tailored designs that offer exceptional flexibility.

By placing a strong emphasis on quality and customization, Vietsteel ensures that its machines perfectly align with the specific needs and preferences of its customers. This approach not only enhances the overall performance and efficiency of the machines but also provides a personalized touch that caters to each customer’s unique requirements.

Vietsteel’s unwavering commitment to delivering flexible machines with custom designs underscores its dedication to ensuring customer satisfaction. By providing distinctive benefits and experiences, the company strives to establish enduring relationships with its customers and contribute to their continued success.

For the most competitive quotation, please do not hesitate to contact Vietsteel at +84 906 898 860. Email: vietsteel@vietsteel.com Website: www.vietsteel.com