Today, metal roofing is very popular because of their excellent advantages such as a variety of thickness, colors and easy construction.

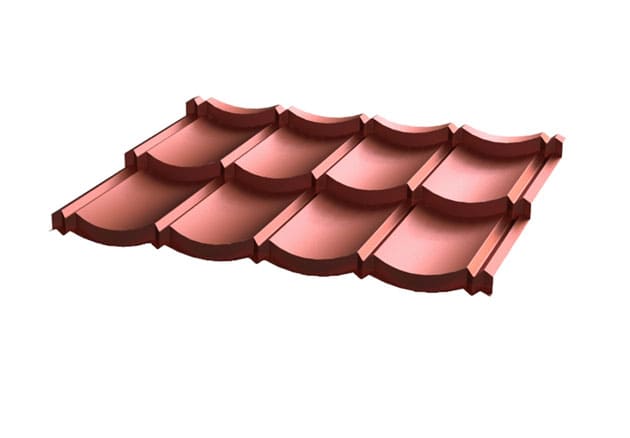

In the past, it was simply flat sheet. However, after a period of improvement, it is believed that corrugated profile has a better hardness than flat metal roofing so that workers can easily execute it, so many kind of step tile profile are developed.

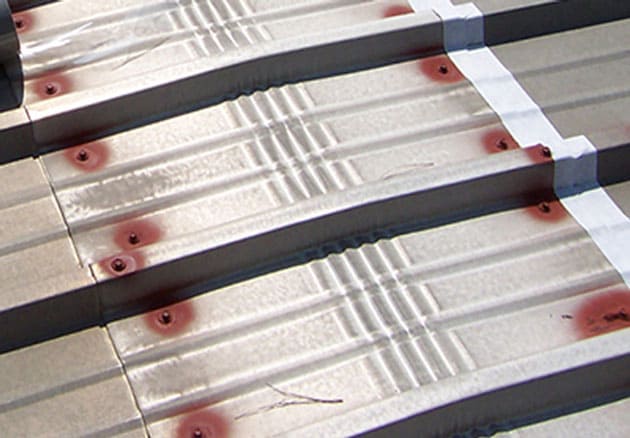

Although the more aesthetic and rigid, but they are still need to use screws for roofing, these bolted positions over time exposed to the sun will rust for the roofing and rainwater will infiltrate inside causing damage works interior.

To solve this problem, Kliplock corrugated sheet was created, they are no longer screwed but associated together by bracket.

Despite rust resistance, there are still gaps between the two sheets. In areas of thunderstorms, rainwater can still follow this opening gap to the inside.

Up to now, the type of corrugated sheet to completely overcome the above disadvantages is the “SEAMLOCK” sheet with the two sides of the Seamlock sheets are folded twice with a special tool to help prevent rain, storm and cyclone.

VietSteel is very proud of the machine that can produce this superior roofing. Not only taking up much space and energy consumption, but also being transported to the base of the building for production thanks to the neat size.