It involves using lightweight metal studs and tracks to create the framework for walls, ceilings, and partitions. Metal framing is known for its durability, and ease of installation. It is also more cost-effective and eco-friendly than wood framing. If you are considering metal stud and track framing for your construction project, it is important to understand the basics of the process and the benefits it offers. Let ‘s understand metal stud and track framing: What you need to know?

1. What is metal stud and track framing?

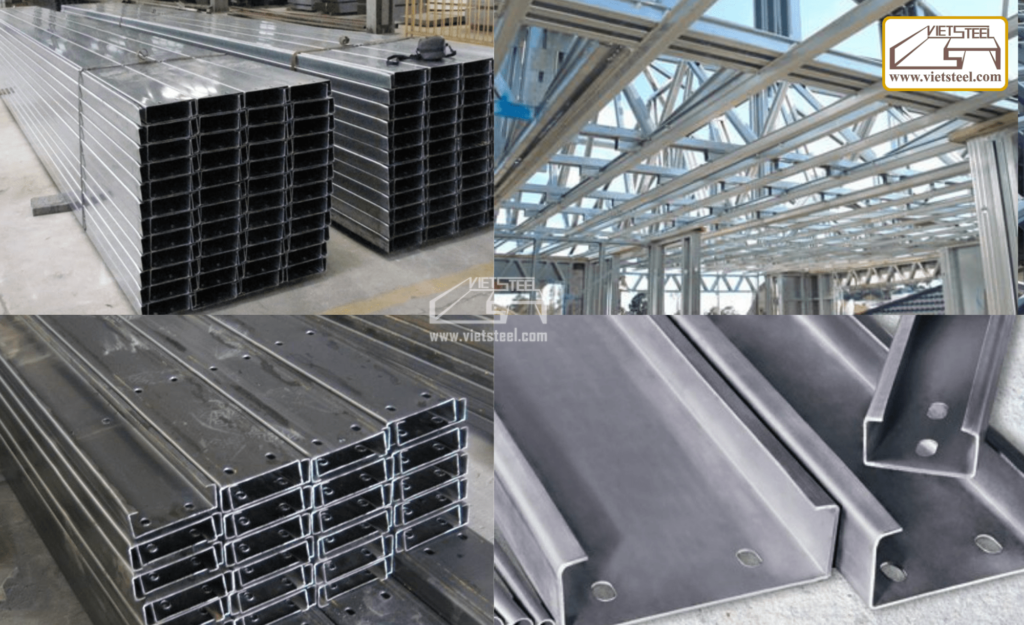

Metal stud and track framing is a construction method that involves using lightweight steel studs and tracks, is an alternative to wood framing and has been popular in commercial construction, to create a framework for walls, ceilings, and partitions in buildings. The studs and tracks are typically made of galvanized steel and come in a variety of sizes and shapes to accommodate different building designs and applications. Metal stud and track framing is popular because it is easy to install, durable, and resistant to fire, insects, and moisture. It is commonly used in commercial, industrial, and residential construction projects..

2. Components of metal stud and track framing

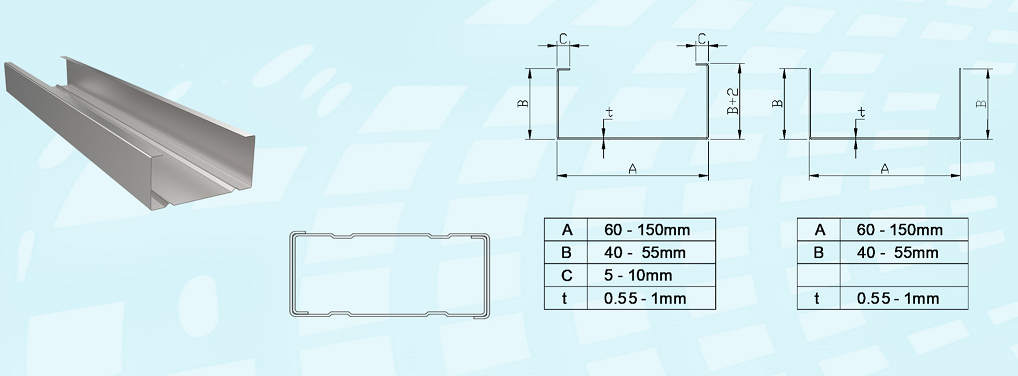

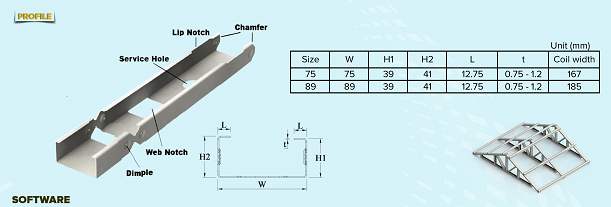

Metal stud and track framing is composed of several components, including furring channels, carrying channels, studs, tracks, wall angle, and main frame channel. The two most commonly used frames are the metal U Track, which serves as the horizontal framework of stud partitions, and the C Stud, which is a lightweight, C-shaped galvanized mild steel section used vertically to form a partition wall or wall lining.

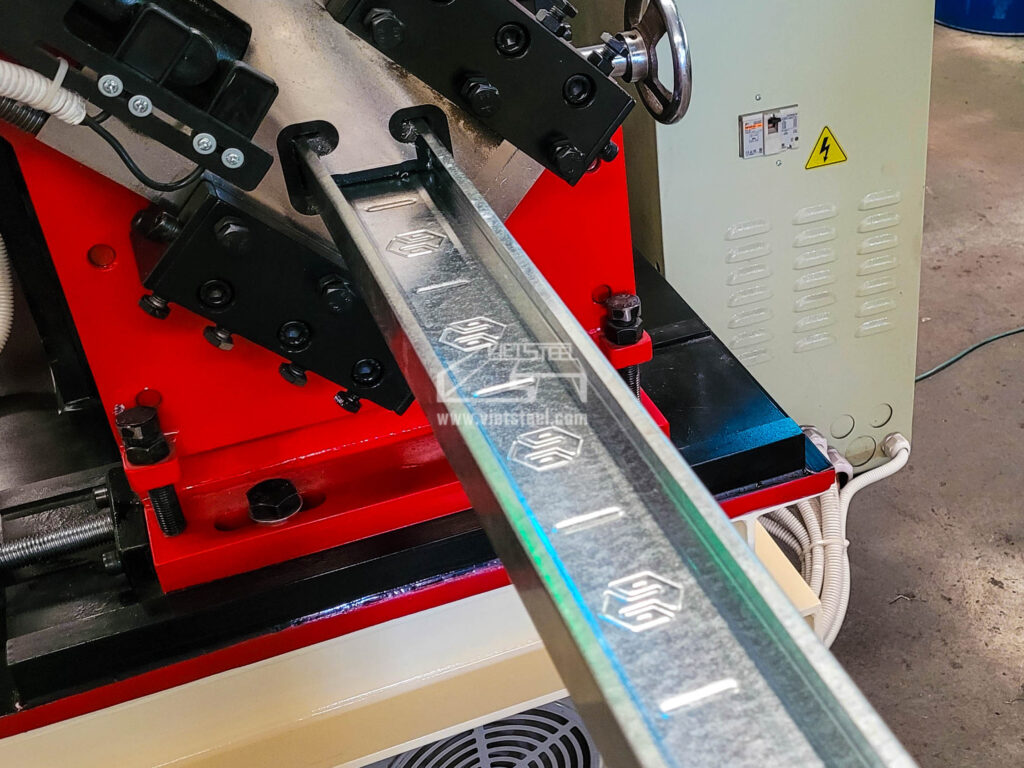

To manufacture C Studs, a coil of galvanized steel is taken and shaped into a “C” shape using a roll forming machine. The studs are then cut into different lengths, automatic cut to length as your orders.

Metal U Track is a versatile and durable galvanized steel section that plays a crucial role in constructing metal wall framing. It serves as the horizontal framework of a partition wall, working in tandem with metal C studs. With an extensive range of sections available, Metal U Track can suit all partition systems. These lightweight steel sections are typically identified by their width, depth, and length.

Metal U Track and C Stud are essential elements of a metal stud and track framing system, which is a cost-effective and lightweight solution for constructing non-load-bearing partition walls. The U Track serves as both the top and bottom plates of the structure, while the C Studs are fixed within the channel created by the U Track. This creates a strong and compact framework that is ideal for partition walls.

3. The advantages of metal stud and track framing

Metal stud and track framing is known for its stability and durability. Unlike wood, metal studs and tracks do not warp or rot, making them an ideal choice for construction projects that require long-lasting, sturdy structures.

Metal studs and tracks are lightweight and easy to carry, making them easy to install. They are attached with screws, which means they can be easily taken apart, changed or moved if necessary.

Metal stud and track framing is known for its superior strength and flexible design. This makes it an ideal choice for construction projects that require strength and versatility.

Metal studs and tracks are impervious to fire as well as termites and ants. This makes them a safer and more reliable choice for construction projects.

Metal studs and tracks are available in custom sizes, which means there is less waste compared to wood.

4. Disadvantages Metal Stud and Track framing

There are a few drawbacks to using metal stud and track framing as a construction method. Firstly, it tends to be more costly than other framing options such as modular or wood framing. Additionally, certain components of the metal framing may need to be treated with non-combustible foam, encased in concrete, or surrounded by fire-resistant drywall to meet building codes and safety standards.

5. Metal Stud and Track rolling forming machine

The C Stud & U Track Roll Forming Machine / U/C Truss Roll Forming Machine, exclusively manufactured by Vietsteel Vietnam, is a fully automated production system that can efficiently produce C Stud and U Track profiles. The machine comes with additional features such as hole punching and custom logo embossing.

| Items | TR-EH Model | TR-HD Model | TR-FL Model |

| Power | – Transmission: 11kw – Motor-Pump:3.7kw | Motor-Pump: 7.5kw | – Transmission: 15kw – Motor-Pump: 5.5kw – Motor-Fly cut:5.5–7.5kw |

| Weight of machine | 4.5 – 5.5 tons | 4 tons | 6 tons |

| Dimension | L= 7-8m; W= 1.2m; H= 1.4m | L=5.8m; W= 0.6m; H=1.4m | L= 9-10m; W= 1.2m; H= 1.4m |

| Forming Speed | 30mpm | 20mpm | 60 mpm |

| Roller stations | 18–20 | 16–18 | 20 – 22 |

| Transmission system | Electric motor and Gear box | Hydraulic Motor | Electric motor and Gear box |

| Cutting system | Hydraulic cylinder | Hydraulic cylinder | Hydraulic cylinder and fly cut by Servo motor |

| Control system | PLC, HMI automatic programmable | PLC, HMI automatic programmable | Motion, HMI automatic programmable |

| Material thickness | 0.5 – 1.2mm | 0.5 – 1.2mm | 0.5 – 1.0mm |

| Material width | 100 – 270 mm | 100 – 270 mm | 100 – 270 mm |

| Material Yield Strength | G450 – G550 Mpa | G450 – G550 Mpa | G450 – G550 Mpa |

| Name | TR-EH Model | TR-HD Model | TR-FL Model |

| PLC | SIEMENS – Germany | Delta – Taiwan | YASKAWA – Japan |

| Touch panel | SIEMENS – Germany | Delta – Taiwan | PROFACE – Japan |

| Encoders | KUBLER – Germany | Autonics – Korea | OMRON– Japan |

| Inverter | YASKAWA – Japan | YASKAWA – Japan | |

| Electric motor | TOSHIBA – Japan | TOSHIBA – Japan | TOSHIBA – Japan |

| Servo motor | YASKAWA – Japan | ||

| Hydraulic components | YUKEN – Japan | YUKEN – Japan | YUKEN – Japan |

| Cutting dies SKD11 | Japan | Japan | Japan |

| Rollers | Alloy steel | Alloy steel | Alloy steel |

| Gear box | Taiwan | Taiwan |

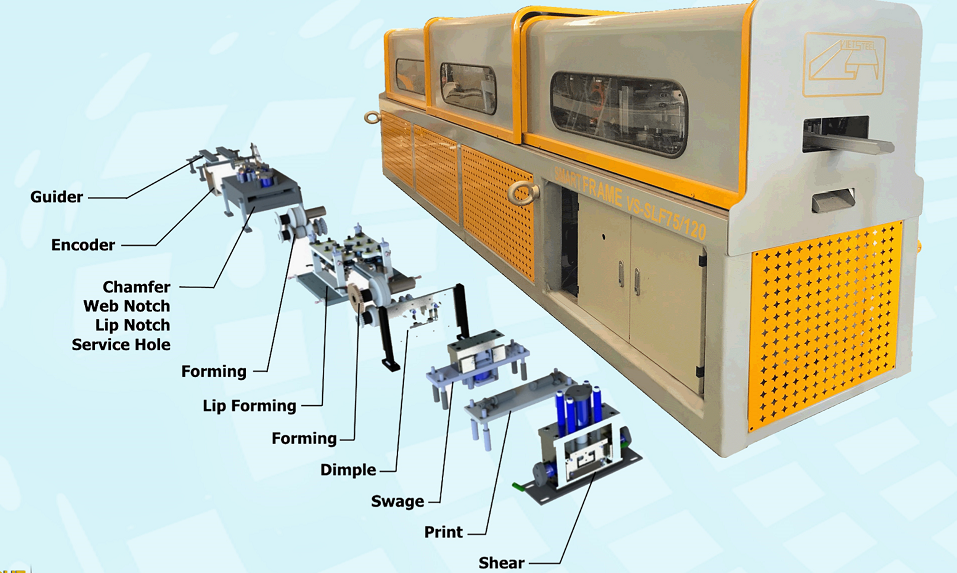

Smartframe System Solution Roll Forming Machine

– A light steel frame design software to extract the estimated volume and cost.

– A software to convert the drawing file to an NC code.

– A monitoring software to control the machine used.

– Smart Light Truss machine modern produces all components according to design automatically

Wall, floor and roof structures are design as module, that ensures quickly installation

| ITEMS | TECHNICAL DATA |

| Electric requirement: | 415V/3ph/50Hz |

| Electric Power: | Servo motor: 11 Kw Hydraulic motor: 7.5 Kw |

| Weight: | 05 tons |

| Machine dimension (LxWxH): | 5m x 1.0m x 1.5m |

| Forming speed: | 28 mpm(without punching) 05-08 mpm(with punching) |

| Roller station: | 12 |

| Transmission system: | Servo motor and gear box |

| Cutting system | Hydraulic cylinder |

| Punching system | Hydraulic Cylinder |

| Control system : | FrameWare Windows based PC for programming & monitoring |

VIETSTEEL is a reputable company in Vietnam that specializes in designing, manufacturing, and installing a wide range of roll forming machines, including purlin roll forming machines, C truss, U Truss, C Stud, U Track, bar rolling machines, and slitting machines.

To buy a metal stud and track, purlin roll forming machine, smartframe system solution from VIETSTEEL, you can contact them through the hotline number +84 906 898 860 or send an email to vietsteel@vietsteel.com to receive detailed pricing and product advice. The purchase of a Metal Stud and Track roll forming machine depends on your needs and requirements, so you can provide additional information about the size, material, and volume of the product you need to produce to receive the best support from VIETSTEEL.”

VIETSTEEL’s products are backed by a 1-year warranty and lifetime maintenance, ensuring their customers receive quality products that are long-lasting and reliable. They have a large team of experienced employees, consisting of more than 140 staff members, and operate from two factories, which have a total area of 18,000m2.

In addition, VIETSTEEL has a special processing workshop that spans 2,000m2 and features the latest technology for CNC milling, CNC turning, wire cutting, and more. This ensures that they are able to preserve the quality of all mechanical parts of their machines and guarantee that the machine can run steadily for 15 years.

For more information on VIETSTEEL’s products and pricing, interested parties can contact our hotline at +84 906 898 860 or send an email to vietsteel@vietsteel.com.