Purlins are structural elements used in building construction to provide support for roof and wall panels. They help distribute the load from the roof or walls to the main structural frame of the building. C purlins and Z purlins are two common types of purlins used in construction, and they have some differences in terms of shape, usage, and structural characteristics. Let’s get started with a comparison of C Purlin and Z Purlin in building construction.

What is a purlin?

A purlin, historically known by various names such as purline, purloyne, purling, or perling, is a vital structural component within the framework of a roof.

It serves as a horizontal beam or bar responsible for providing essential structural support in a building, typically situated beneath the roof. Purlins can be supported by the building’s rafters or its walls, and while they are commonly found in metal constructions, they can also replace closely spaced rafters in wood-framed structures.

Function of Purlin in Building Construction

The primary function of purlins is to bear the weight of the roof deck, which is the surface layer of the roof, typically composed of wooden panels, plywood, or sheet metal. This roof deck is further protected with weatherproofing materials and often incorporates insulation.

Purlins come in various types, categorized based on the materials and shapes used in their construction, and they have versatile applications, including supporting structural walls or floors. Without purlins, the roof lacks a sturdy framework for the roofing material to rest on, underscoring their significance in the overall stability of a roof structure.

They are particularly common in metal buildings and are essential for ensuring the integrity and strength of the roof structure.

In steel construction, purlins are essential components that serve specific functions:

Roof Framing: Purlins in steel construction are typically used as roof framing members. They run parallel to the building’s eave, providing structural support for the roof decking or sheeting. They play a critical role in maintaining the roof’s integrity and load-bearing capacity.

Support: Purlins are supported by other structural elements such as rafters or walls. They help distribute the weight of the roof and any additional loads evenly across the building’s framework.

Metal Building Systems: Purlins are commonly utilized in Metal Building Systems, where they are often shaped as Z-sections to provide flexural continuity between spans. This design enhances the structural strength and stability of the roof.

Structural Shapes: In the steel industry, purlins and other structural members have representative designations for easy reference in drawings and documentation. Channel sections are typically denoted as C shapes, with or without flange stiffeners. U shapes are used to represent channel sections without flange stiffeners, while Z shapes refer to point-symmetric sections shaped like the letter Z.

Cold-Formed Steel: Purlins and similar secondary members, such as girts for walls, are often made from cold-formed steel. These members can be C, Z, or U sections, and they may be either cold-formed or mill-rolled. Cold-formed sections can be efficient in terms of weight, especially for secondary applications.

Efficient Design: Z-section purlins are sometimes nested for transportation, making them easier to transport and handle. Additionally, these sections can be lapped at the supports, creating a structurally efficient continuous beam that spans multiple support points.

C purlins and Z purlins are both types of structural members used in construction, but they have distinct differences in their shapes and applications:

C Purlin vs Z Purlin Comparison

C Purlin

Shape: C purlins are named for their C-shaped cross-section. They have one vertical flat section with two horizontal flanges on the top and bottom.

Main Usage: C purlins are primarily used for supporting walls and floors. They are suitable for creating the structural framework for walls and floor joists in buildings. C purlins can also be used to support the beams required for flooring.

Applications: C purlins find use in various applications, including door mounting, roof clipping, window trimming, parapet rails, and side rails. They are versatile and can serve multiple purposes in building construction.

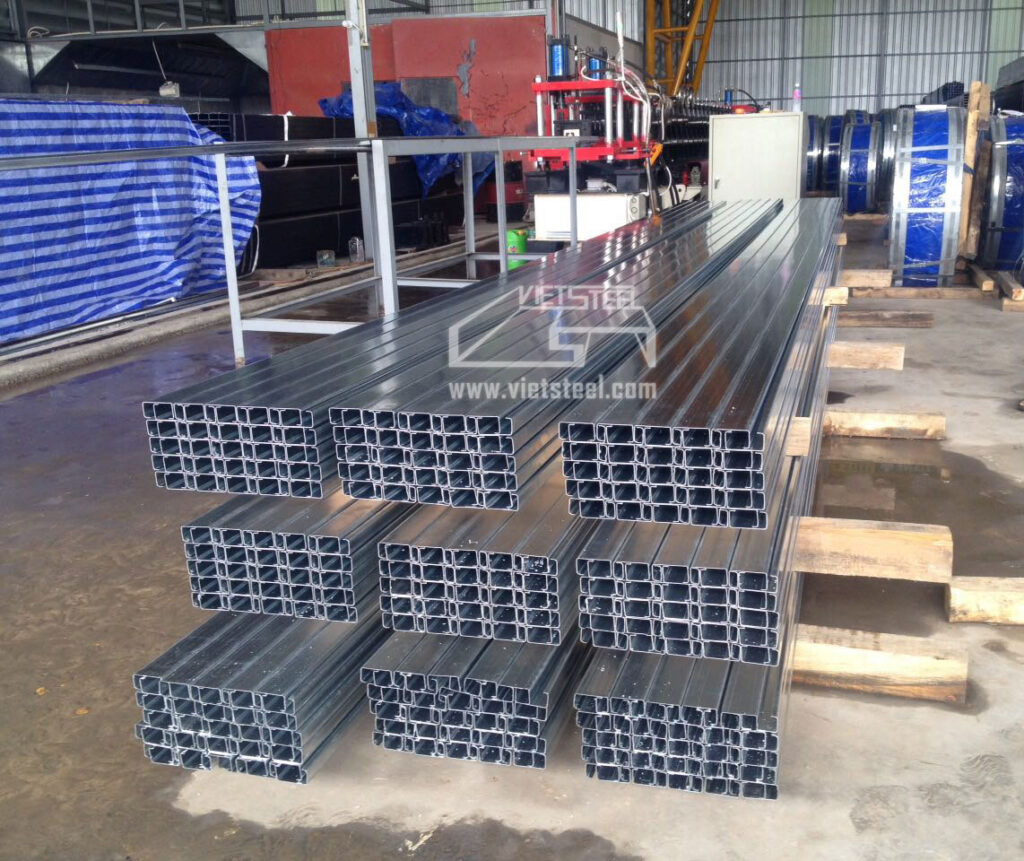

Roll Forming Machine: A C purlin roll forming machine is used to continuously produce C-shaped steel channels from galvanized or cold-rolled steel strips. This machine performs processes such as feeding, hole punching, bending, and cutting.

Z Purlin

Shape: Z purlins are named for their Z-shaped cross-section. They have a vertical section in the middle with flanges angling outwards at the top and bottom, forming a Z shape.

Main Usage: Z purlins are mainly used to support the roof and wall joists in a building. They are positioned between the roofing sheets and the building’s structure, providing support for the roofing material to ensure it remains securely attached and in place.

Applications: Z purlins are commonly used in agricultural and industrial buildings due to their flexibility and lightweight properties. They are often employed where roof and wall support is crucial, and they can be adapted for use in various sizes.

Roll Forming Machine: A Z purlin roll forming machine, which is a type of channel roll forming machine, is used to create Z-shaped purlin profiles. By adjusting the rollers on this machine, you can produce different sizes and configurations of Z purlins.

C purlin & Z Purlin Comparition

C purlins are typically used for walls and floors and have a C-shaped cross-section, while Z purlins are used for roof and wall support and have a Z-shaped cross-section. The choice between C and Z purlins depends on the specific requirements of a building’s construction and the load-bearing needs.

Now that you understand the Difference between C purlin and Z purlin and you are ready to get a quotation of the C Purlin and Z Purlin roll forming machine or combine CZ Purlin roll forming machine. Our sales reps have decades of experience with metal panel roll former and would be happy to assist you. For more information on different types or you are ready to purchase please contact our consultant today.

To give a better quotation and meet exactly your requirements, could you advise detailed information as below:

- Which kind of roof roll forming machines do you need?

- Profile or sample’s pictures

- Thickness and width of the coil

Get a quotation for CZ Purlin Roll Forming Machine by Vietsteel, please contact with us:

Hotline: +84906 898860

Email: vietsteel@vietsteel.com

Website: www.vietsteel.com