By using SmartFrame technology, the construction process can become more efficent, cost-effective, and accurate. The use of light steel buildings can also have various benefits, such as faster construction times, reduced waste, and improved sustainability.

As of the information you provided, SmartFrame technology has been applied in countries like New Zealand, Australia, Canada, and potentially other regions as well.

What’s SmartFrame Solution System?

Smartframe is a technological solution from Australia, end to end from designing to building a civil house.

SmartFrame solution is a solution that was created using the designs, manufacturing and construction of light steel buildings to replace tradition construction methods and was made possible by Smartframe machines and a specialized design software. It could include various software tools, platforms, or systems that facilitate different aspects of the construction process, such as architectural design, engineering calculations, project management, and construction planning.

SmartFrame is a technological solution that aims to revolutionize the construction industry, particularly in the domain of light steel buildings.

Key points about SmartFrame solution:

Purpose: SmartFrame aims to replace traditional construction methods with a more efficient and innovative approach that leverages light steel building technology.

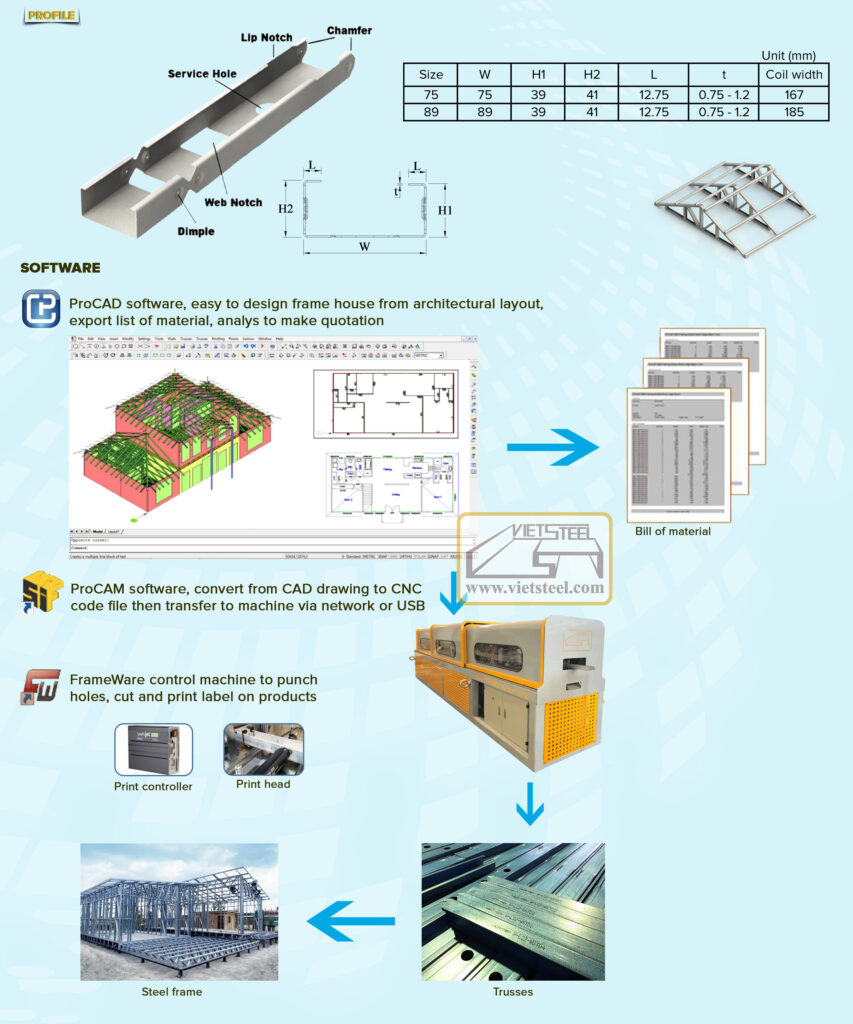

Components: The solution involves two main components: specialized machines and design software.

- SmartFrame Machines: These machines play a crucial role in the manufacturing process. They are capable of rolling steel products into the correct shapes and sizes as per the designs and drawings made by the design software.

- Design Software: The specialized design software likely enables architects and engineers to create precise designs and drawings for the light steel buildings. These designs are then used by the SmartFrame machines during the manufacturing process.

By using SmartFrame technology, the construction process can become more efficient, cost-effective, and accurate. The use of light steel buildings can also have various benefits, such as faster construction times, reduced waste, and improved sustainability.

As of the information you provided, SmartFrame technology has been applied in countries like New Zealand, Australia, Canada, and potentially other regions as well.

That’s reason you should choose SmartFrame Solution System by Vietsteel.

1. What is the purpose of SmartFrame Solution?

SmartFrame is a technological solution that seeks to replace traditional construction methods with a more efficient and innovative approach. It’s light steel building technology to achieve this goal. By using specialized machines and design software, SmartFrame enables faster and easier construction of buildings made from light steel materials. This approach offers advantages such as quicker assembly, reduced environmental impact, and structures that are durable and lightweight.

2. What are the components of SmartFrame Solution?

SmartFrame involves the use of specialized machines and design software to streamline the construction process for light steel buildings.

2.1. SmartFrame Machines

These machines are essential in the manufacturing process of light steel buildings. They have the capability to roll steel products into the correct shapes and sizes as specified in the designs and drawings created by the specialized design software. These machines play a critical role in ensuring the precision and accuracy of the components used in the construction of the building.

2.2. Design Software

The specialized design software is a crucial tool for architects and engineers involved in the construction project. It enables them to create precise and detailed designs and drawings for the light steel buildings. These designs are then used as input for the SmartFrame machines during the manufacturing process. The design software ensures that the components are tailored to the specific requirements of the building, optimizing efficiency and reducing waste.

By combining the capabilities of SmartFrame machines and the specialized design software, the construction process becomes more efficient, allowing for quicker assembly and reducing the environmental impact. The use of light steel materials also contributes to creating durable and lightweight structures, meeting the construction industry’s objectives for sustainable and innovative building solutions.

3. What are the advantages of this solution?

– Non welding, non painting and friendly environment

– High durability, C-truss section used for all frame optimizes the force bearing

– Beautiful, flexible architecture, suitable for a variety of architectures and customer needs

– Fast construct, save 30-50% time to build your house

4. Using which software? What are the advantages of the software?

– Software integrate: Design, structure calculation, data export…

– Calculate load forces: snow, wind, dynamic load, static load, and analysis structure

– Manage order history, customer and production diary…

– Export drawings, Bill of material, construction, installation instructions drawings

The SmartFrame system integrates automated production control, manages order history, customer information, and shipping records. It publishes detailed drawings, exports material orders, and provides installation guide sheets.

The system is controlled automatically through computer integration and utilizes high-speed printers for labeling each component. The precision machining of parts ensures simple and fast assembly.

The structural framework, walls, floors, and roofs are modular, guaranteeing swift installation.

5. Softwares used in the Smartframe solution includes:

– A light steel frame design software to extract the estimated volume and cost.

– A software to convert the drawing file to an NC code.

– A monitoring software to control the machine used.

With the integration of Procad and Procam software along with the Smartframe Roll Forming Machine, this production line has the capability to automatically design the entire framework of a light steel house, including floors, wall frames, and roofs, quickly and efficiently. It can calculate all the details of the order within a few minutes of operation.

Procad is a comprehensive design and calculation software solution. Despite its sophisticated functionalities, it has a user-friendly interface that allows even individuals with limited design and structural experience to operate it effectively. Starting from the initial database with architectural layout drawings, the software automatically performs calculations and generates order summaries and assembly details.

The Procam software plays an intermediary role, transferring design data from Procad to the roll forming machine.

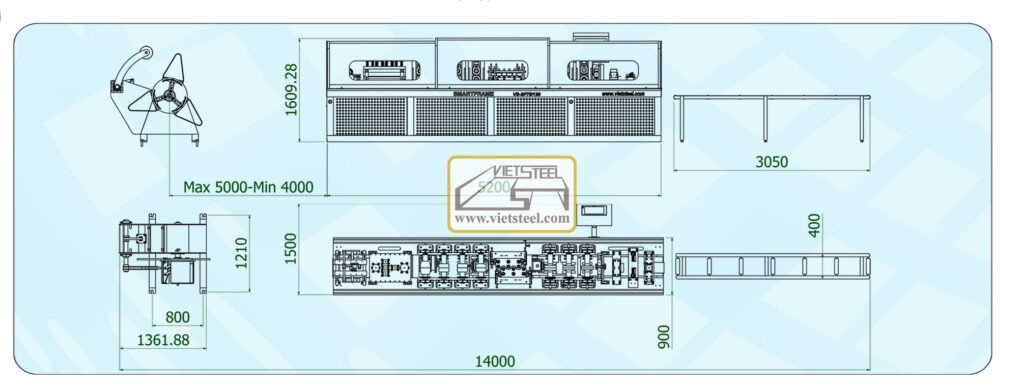

6. What kinds of machines use to produce SmartFrame?

– Smart Light Truss machine modern produces all components according to design automatically

– Machine is controlled by computer, integrated high speed inkjet printer, print code in all component. Components are processed precisely; assembled quickly, simple

Wall, floor and roof structures are design as module, that ensures quickly installation

The house designs are diverse and follow architectural drawings, with internal force calculations ensuring the ability to withstand wind speeds of up to 270 km/h, meeting European quality standards.

The Smartframe Solution System Machine is a fully automated production system that manufactures high-strength steel frames with aluminum-zinc coating, providing corrosion resistance for harsh climates and durability lasting hundreds of years. Designed and manufactured using Australian technology and European standards, the machine has 7 pairs of independent rolling axes and two punching stations: one for the body, wings, and edges, and the other for creating screw holes. Additionally, it integrates a small deburring tool for connecting elements and an inkjet coding system for easy operation and management.

This synchronized technical standardization, being produced on an industrial assembly line, lowers costs by 10-30% compared to traditional materials. The Smartframe system is a modern, efficient, and cost-effective solution that is gaining popularity in European countries and is gradually expanding in domestic and Southeast Asian markets.

Vietsteel Machinery takes pride in being the first unit in Vietnam to successfully manufacture and introduce the Smartframe system, an intelligent lightweight steel house manufacturing system, to the market. With our available resources and extensive experience, we are fully confident in delivering success on every project that we undertake. Our commitment to excellence and innovation ensures that each construction we create will be a testament to our capabilities and dedication to providing top-notch solutions.

More information about Smartframe Solution System Machine, contact with us:

Hotline: +84 906 898 860

Email: vietsteel@vietsteel.com

Website: www.vietsteel.com