The C truss roll forming machine is a popular machine used in the sheet metal, construction, and manufacturing industries to produce galvanized steel roof trusses. One of the main advantages of this machine is that it allows for the creation of beautifully customized designs. Additionally, it has a strong body frame and is easy to operate, providing a stable and reliable production process. These machines are available at a reasonable price, making them a cost-effective choice for those looking to produce high-quality roof trusses.

1. What is C truss roll forming machine?

C truss roll forming machine is a type of industrial equipment that is used to manufacture C-shaped steel trusses. The machine uses a continuous process to bend and shape metal coils into the desired truss profile.

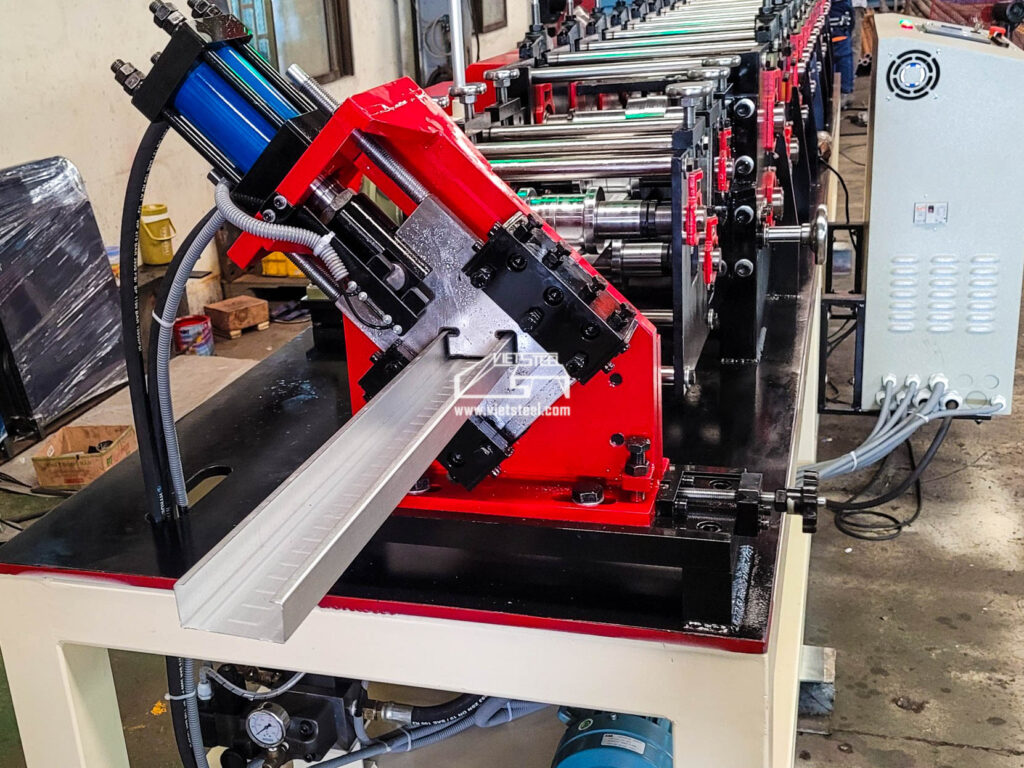

The process begins with a steel coil being fed into the machine, where it is first uncoiled and then passed through a series of rollers that gradually shape it into the desired C-shaped profile. As the steel moves through the machine, it is also cut to the appropriate length, and any necessary holes or notches are punched into the metal.

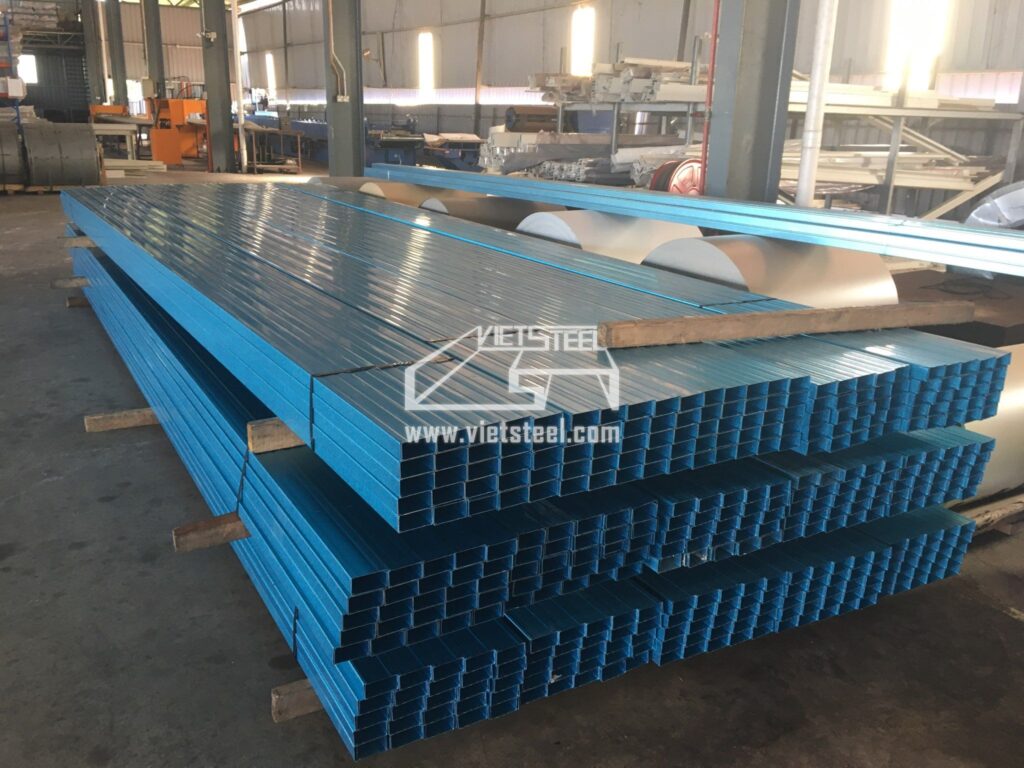

C trusses are commonly used in the construction industry to provide structural support for roofs, walls, and other building components. They are popular because they are lightweight, yet strong, and can be quickly and easily assembled on site. C truss roll forming machines allow manufacturers to produce large quantities of trusses efficiently and with high precision, making them an essential tool for many construction projects.

The C truss roll forming machine is a popular machine used in the sheet metal, construction, and manufacturing industries to produce galvanized steel roof trusses. One of the main advantages of this machine is that it allows for the creation of beautifully customized designs. Additionally, it has a strong body frame and is easy to operate, providing a stable and reliable production process. These machines are available at a reasonable price, making them a cost-effective choice for those looking to produce high-quality roof trusses.

2. Application of C Truss Vietsteel

C truss are primarily used in the construction industry to manufacture C-shaped steel trusses for various applications. Some of the common applications of C trusses include:

Roofing: C trusses are commonly used in roofing applications to provide support for roof decks and to distribute the weight of the roof evenly across the structure.

Wall framing: C trusses are used in wall framing applications to provide support for exterior and interior walls. They can also be used to create curved walls and partitions.

Floor systems: C trusses can be used in floor systems to support floor decking and to provide a stable platform for other building components.

Bridges: C trusses can be used in the construction of bridges to provide structural support for the roadway.

Industrial buildings: C trusses are often used in the construction of industrial buildings to provide support for heavy equipment and machinery.

3 . Specification for C truss Roll Forming Machine

Specification for C truss Roll Forming Machine size TR-EH: [Click here]

Video for C truss machine size TR-EH [Click here]

Specification for C truss Roll Forming Machine size TR – FL [Click here]

Video for C truss machine size TR-FL [Click here]

Specification for C truss Roll Forming Machine size TR – HD [Click here]

Video for C truss machine size TR-HD [Click here]

| Items | TR-EH Model | TR-HD Model | TR-FL Model |

| Power | – Transmission: 11kw – Motor-Pump:3.7kw | Motor-Pump: 7.5kw | – Transmission: 15kw – Motor-Pump: 5.5kw – Motor-Fly cut:5.5–7.5kw |

| Weight of machine | 4.5 – 5.5 tons | 4 tons | 6 tons |

| Dimension | L= 7-8m; W= 1.2m; H= 1.4m | L=5.8m; W= 0.6m; H=1.4m | L= 9-10m; W= 1.2m; H= 1.4m |

| Forming Speed | 30mpm | 20mpm | 60 mpm |

| Roller stations | 18–20 | 16–18 | 20 – 22 |

| Transmission system | Electric motor and Gear box | Hydraulic Motor | Electric motor and Gear box |

| Cutting system | Hydraulic cylinder | Hydraulic cylinder | Hydraulic cylinder and fly cut by Servo motor |

| Control system | PLC, HMI automatic programmable | PLC, HMI automatic programmable | Motion, HMI automatic programmable |

| Material thickness | 0.5 – 1.2mm | 0.5 – 1.2mm | 0.5 – 1.0mm |

| Material width | 100 – 270 mm | 100 – 270 mm | 100 – 270 mm |

| Material Yield Strength | G450 – G550 Mpa | G450 – G550 Mpa | G450 – G550 Mpa |

| Name | TR-EH Model | TR-HD Model | TR-FL Model |

| PLC | SIEMENS – Germany | Delta – Taiwan | YASKAWA – Japan |

| Touch panel | SIEMENS – Germany | Delta – Taiwan | PROFACE – Japan |

| Encoders | KUBLER – Germany | Autonics – Korea | OMRON– Japan |

| Inverter | YASKAWA – Japan | YASKAWA – Japan | |

| Electric motor | TOSHIBA – Japan | TOSHIBA – Japan | TOSHIBA – Japan |

| Servo motor | YASKAWA – Japan | ||

| Hydraulic components | YUKEN – Japan | YUKEN – Japan | YUKEN – Japan |

| Cutting dies SKD11 | Japan | Japan | Japan |

| Rollers | Alloy steel | Alloy steel | Alloy steel |

| Gear box | Taiwan | Taiwan |

4. Common characteristics of C truss roll forming machine

The machine is equipped with an encoder to provide signal feedback on the length of the product, and a control panel that enables the user to count the total length of finished coil.

The rollers of the machine are made of alloy steel and are fabricated using CNC precision machines, which ensures high precision in the manufacturing process. The rollers are hard chromium plated, which increases their durability and resistance to wear and tear.

The cutting die is made of SKD11 steel and is fabricated using CNC machines. The die undergoes thermal treatment to achieve a hardness of 55-60HRC, which makes it highly durable and resistant to wear and tear.

The machine is equipped with a hydraulic system that has a cooling system, which enables it to operate continuously for 20-22 hours per day. This ensures that the machine can be used for long periods without any interruption, which increases its productivity and efficiency.

5. Quotation for C truss Vietsteel Machinery Co., LTD

VIETSTEEL is a reputable company in Vietnam that specializes in designing, manufacturing, and installing a wide range of roll forming machines, including purlin roll forming machines, C truss, bar rolling machines, and slitting machines. They offer 4 lines of double deck roll forming machines, consisting of 8 different models, at reasonable prices.

To buy a C purlin roll forming machine from VIETSTEEL, you can contact them through the hotline number +84 906 898 860 or send an email to vietsteel@vietsteel.com to receive detailed pricing and product advice. The purchase of a C purlin roll forming machine depends on your needs and requirements, so you can provide additional information about the size, material, and volume of the product you need to produce to receive the best support from VIETSTEEL.”

VIETSTEEL’s products are backed by a 1-year warranty and lifetime maintenance, ensuring their customers receive quality products that are long-lasting and reliable. They have a large team of experienced employees, consisting of more than 140 staff members, and operate from two factories, which have a total area of 18,000m2.

In addition, VIETSTEEL has a special processing workshop that spans 2,000m2 and features the latest technology for CNC milling, CNC turning, wire cutting, and more. This ensures that they are able to preserve the quality of all mechanical parts of their machines and guarantee that the machine can run steadily for 15 years.

For more information on VIETSTEEL’s products and pricing, interested parties can contact our hotline at +84 906 898 860 or send an email to vietsteel@vietsteel.com.