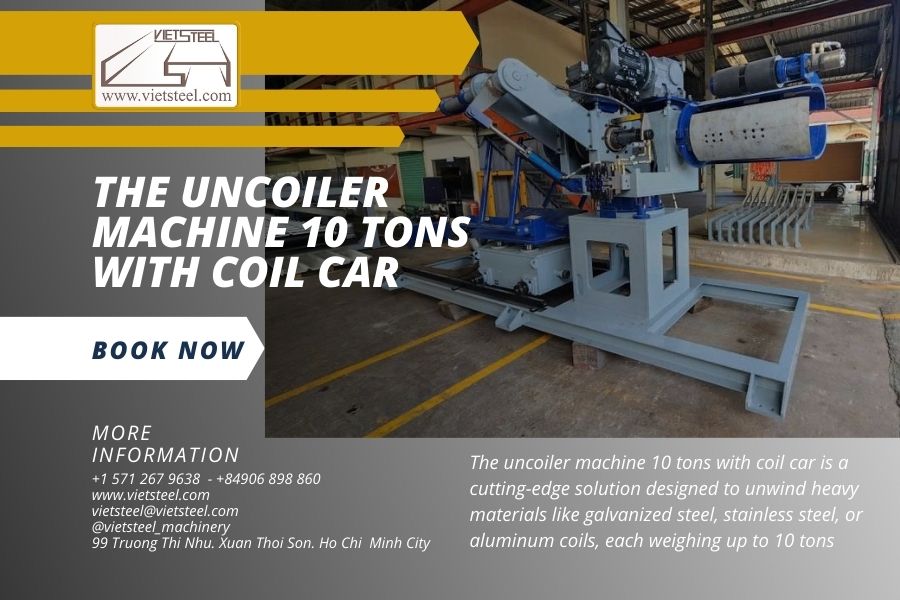

The uncoiler machine 10 tons with coil car is a cutting-edge solution designed to unwind heavy materials like galvanized steel, stainless steel, or aluminum coils, each weighing up to 10 tons. This advanced equipment ensures a steady and precise material feed for industrial production lines, such as roll-forming or slitting systems. With its automated dual-head design and integrated coil car, this uncoiler optimizes efficiency, reduces downtime, and enhances output in high-demand manufacturing environments.

The uncoiler machine 10 tons with coil car, also referred to as a dual-head uncoiler, is engineered to manage two coils simultaneously or alternately. Equipped with a hydraulic or mechanical system, it synchronizes material unwinding with production lines. Unlike single uncoilers, this machine features two mandrels and a coil car for seamless coil switching, eliminating the need to halt operations for reloading.

Nội dung chính

Key Features of the Uncoiler Machine 10 Tons with Coil Car

High Load Capacity: Handles coils up to 10 tons, delivering robust performance for industrial applications.

Precision Material Delivery: Provides uniform and accurate unwinding, essential for processes requiring high precision, such as metal forming or cutting.

The uncoiler machine 10 tons with coil car, also referred to as a dual-head uncoiler, is engineered to manage two coils simultaneously or alternately. Equipped with a hydraulic or mechanical system, it synchronizes material unwinding with production lines. Unlike single uncoilers, this machine features two mandrels and a coil car for seamless coil switching, eliminating the need to halt operations for reloading.

How It Works: Step-by-Step Process

The uncoiler machine 10 tons with coil car operates through an automated, streamlined workflow:

90-Degree Coil Alignment: The coil car rotates the loaded coil 90 degrees to align it with the machine’s mandrel.

Positioning Pin Release: A pin is raised to free the coil, preparing it for mounting.

Precise Coil Elevation: The hydraulic coil car lifts the coil to align its core with the mandrel’s center.

Coil Car Movement: The coil car glides along guide rails to position the coil onto the mandrel.

Mandrel Clamping: Hydraulic expanding arms secure the coil’s inner core (508–610 mm diameter).

Snubber Roll Activation: A snubber roll presses the coil’s leading edge to prevent uncontrolled unwinding, ensuring safety.

Coil Car Reset: The coil car lowers and returns to its starting position, ready for the next coil.

New Coil Preparation: The coil car is set to receive another coil from an overhead crane.

Technical Specifications

Hydraulic System: Powered by a 5–7.5 kW motor, it controls the expanding arms and snubber roll, supporting up to 10 tons of clamping force.

Photoelectric Sensors: Detect coil alignment and automatically pause operations if misalignment occurs.

PLC Control: A programmable logic controller ensures synchronized operation with the production line, enhancing the efficiency of the uncoiler machine 10 tons with coil car.

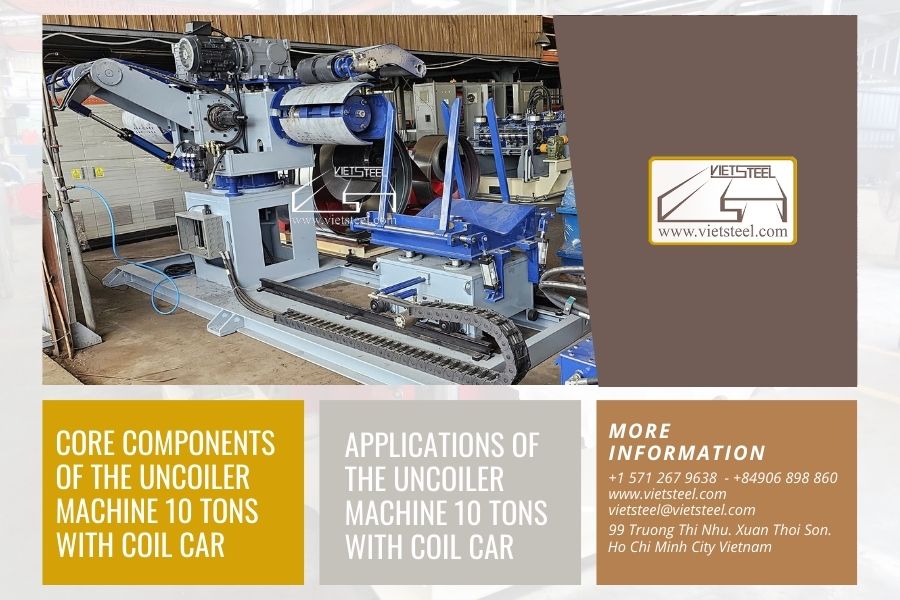

Core Components of the Uncoiler Machine 10 Tons with Coil Car

Main Frame:

Built from welded steel plates, capable of supporting 5–15 tons per coil.

Features a 180° rotating or parallel design to accommodate dual mandrels.

Dual Mandrels:

Each mandrel includes hydraulically controlled expanding arms, suitable for coils with inner diameters of 508–610 mm.

Load capacity: 5–10 tons per mandrel, depending on the model.

Hydraulic System:

A 5–7.5 kW motor powers coil unwinding and mandrel rotation.

Hydraulic pistons maintain material tension, preventing twists or breaks.

Control System:

Equipped with Siemens or Mitsubishi PLC and an HMI touchscreen for adjusting speed and cutting length.

Inverter technology synchronizes the uncoiler machine 10 tons with coil car with downstream equipment.

Photoelectric sensors and a loop accumulator ensure straight material feed.

Braking System:

Pneumatic or hydraulic brakes enable instant stopping for safety.

Loop Pit:

Positioned between the uncoiler and production line, it prevents material buildup when unwinding and processing speeds differ.

Applications of the Uncoiler Machine 10 Tons with Coil Car

The uncoiler machine 10 tons with coil car is a versatile tool used in various industries

Steel and Metal Fabrication:

Unwinds galvanized, stainless steel, or aluminum coils for producing roofing panels, C/Z/U purlins, or gutters.

Ideal for roll-forming and slitting lines.

Metal Processing:

Processes cold-rolled or hot-rolled steel for automotive parts or electrical components.

Supports manufacturing of steel pipes and structural channels.

Industrial Construction:Supplies materials for prefabricated buildings, warehouses, or insulated panels.

Specialized Applications: Can be customized to handle plastic films or paper for printing and packaging industries.

Benefits of the Uncoiler Machine 10 Tons with Coil Car

Seamless Coil Switching Dual mandrels enable one coil to unwind while preparing another, reducing downtime to under one minute.

Material Versatility Handles thin (0.3 mm) to thick (3 mm) sheets and high-strength steel up to 550 MPa.

High Output Perfect for large-scale factories producing over 1,000 tons monthly, particularly in industrial zones

Advantages of the Uncoiler Machine 10 Tons with Coil Car

Compared to single or manual uncoilers, Vietsteel’s uncoiler machine 10 tons with coil car delivers unmatched benefits:

50–70% Productivity Increase:

Continuous unwinding eliminates downtime for coil changes, ideal for 24/7 operations.

Unwinding speeds of 40–60 m/min, double that of single uncoilers.

Reduced Labor Costs:

Requires only 1–2 operators, cutting labor needs by up to 80% compared to manual systems.

Automated PLC controls minimize manual adjustments.

Exceptional Accuracy:

Photoelectric sensors and loop accumulators ensure straight material delivery with <±0.5 mm error.

Automatic braking reduces material waste to under 1%.

Time-Saving Flexibility:

Switches between coils (e.g., thick and thin sheets) in seconds using rotating or parallel mandrels.

Link products The uncoiler 10 tons with coil car

Compatible with various profiles when integrated with roll-forming machines.

Safety and Longevity: High-strength steel frame and chrome-plated mandrels offer a 10–15-year lifespan.

Includes emergency stop buttons, safety sensors, and automatic error alerts.

Drawbacks and Considerations

Initial Investment: The uncoiler machine 10 tons with coil car is pricier than single uncoilers, making it less ideal for small workshops.

Maintenance Needs: Requires regular checks of hydraulic fluid and sensors, plus operator training for PLC systems.

Space Requirements: Occupies significant space (3–5 m long, 2 m wide), necessitating a large factory.

Line Dependency: Maximizes efficiency when paired with automated roll-forming or slitting lines; standalone use may limit dual-head benefits.

Vietsteel’s Uncoiler Machine 10 Tons with Coil Car

Flagship Model: Vietsteel’s UC-E Hydraulic Uncoiler features a dual-head design with a 5–10-ton capacity per coil, seamlessly integrating with roll-forming lines like the CZ-EA model.

Customization Options: Offers add-ons like punching stations, servo cutting, or multi-purpose roll-forming compatibility.

Contact Information:

Website: vietsteel.com – Includes demo videos and product catalogs.

Email: vietsteel@vietsteel.com

Hotline: 84 906 898 860 – Use the website’s contact form for detailed quotes.

Comparison: Uncoiler Machine 10 Tons with Coil Car vs. Single Uncoiler

Uncoiler Machine 10 Tons with Coil Car

Single Uncoiler

Number of Coils 2 (simultaneous or alternating) and 1

Switching Time <1 minute (automatic mandrel rotation) 5–10 minutes (manual coil replacement)

Speed 40–60 m/min 20–40 m/min

Reference Applications Large factories, high output Small to medium workshops

Recommendations for Users

View a Demo: Explore vietsteel.com or Vietsteel’s YouTube channel to see the uncoiler machine 10 tons with coil car in action.

Get a Quote: Contact Vietsteel via email vietsteel@vietsteel.com or hotline +84 906 898 860, specifying load capacity (5 or 10 tons), material type (steel, aluminum, etc.), and connected production lines for a customized quote.