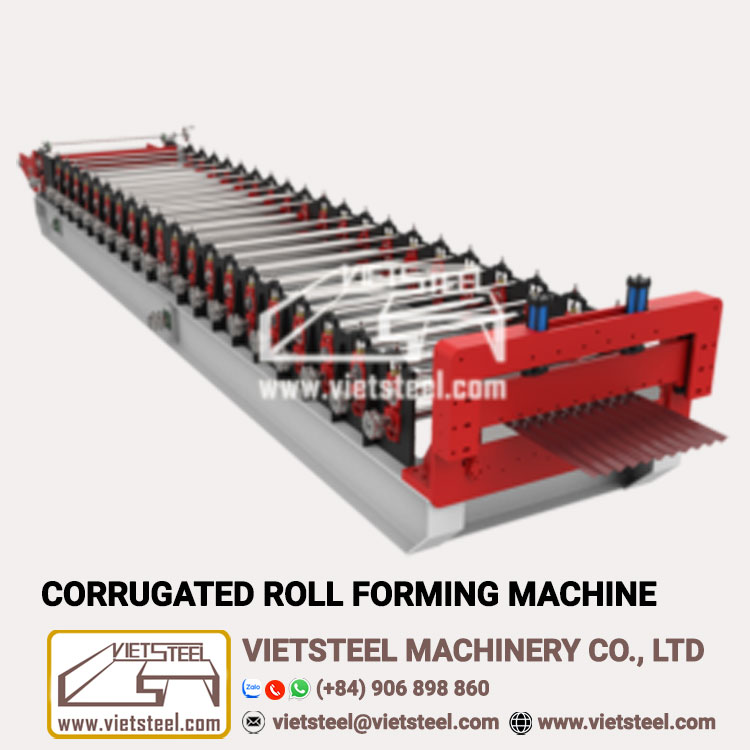

Descripción

– Power: Motor – Pump: 11 – 22 kw

– Weight of machine: 14 – 18 tons

– Dimension: L=12-14m; W=1.5-2.0m; H=1.6m

– Forming speed: 20 meters/minute

+ 3 meters x 6.5 pcs/min

– Power: Motor – Pump: 11 – 22 kw

– Weight of machine: 14 – 18 tons

– Dimension: L=12-14m; W=1.5-2.0m; H=1.6m

– Forming speed: 18 – 20 meters/minute

+ 2 meters x 7 pcs/min

+ 3 meters x 6 pcs/min

+ 4 meters x 5 pcs/min- Power: Motor – Pump: 11 – 22 kw

– Weight of machine: 14 – 18 tons

– Dimension: L=12-14m; W=1.5-2.0m; H=1.6m

– Forming speed: 18 – 20 meters/minute

+ 2 meters x 7 pcs/min

+ 3 meters x 6 pcs/min

+ 4 meters x 5 pcs/min- Power: Motor – Pump: 11 – 22 kw

– Weight of machine: 14 – 18 tons

– Dimension: L=12-14m; W=1.5-2.0m; H=1.6m

– Forming speed: 18 – 20 meters/minute

+ 2 meters x 7 pcs/min

+ 3 meters x 6 pcs/min

+ 4 meters x 5 pcs/min- Power: Motor – Pump: 11 – 22 kw

– Weight of machine: 14 – 18 tons

– Dimension: L=12-14m; W=1.5-2.0m; H=1.6m

– Forming speed: 18 – 20 meters/minute

+ 2 meters x 7 pcs/min

+ 3 meters x 6 pcs/min

+ 4 meters x 5 pcs/min- Power: Motor – Pump: 11 – 22 kw

– Weight of machine: 14 – 18 tons

– Dimension: L=12-14m; W=1.5-2.0m; H=1.6m

– Forming speed: 18 – 20 meters/minute

+ 2 meters x 7 pcs/min

+ 3 meters x 6 pcs/min

+ 4 meters x 5 pcs/min- Power: Motor – Pump: 11 – 22 kw

– Weight of machine: 14 – 18 tons

– Dimension: L=12-14m; W=1.5-2.0m; H=1.6m

– Forming speed: 18 – 20 meters/minute

+ 2 meters x 7 pcs/min

+ 3 meters x 6 pcs/min

+ 4 meters x 5 pcs/min